© Bomeca S.r.l. unipersonale

REA 301252 – Reg.Imp.VI 97572

P.Iva 03130780244

Strada del Capitello 3/5

36075 Montecchio Maggiore

(Vicenza) – Italy

T. +390444696680

F. +390444490528

PRODOTTI

• Serbatoi

• Attrezzature per l’industria

• Trasportatori sfridi

LAVORAZIONI

• Progettazione

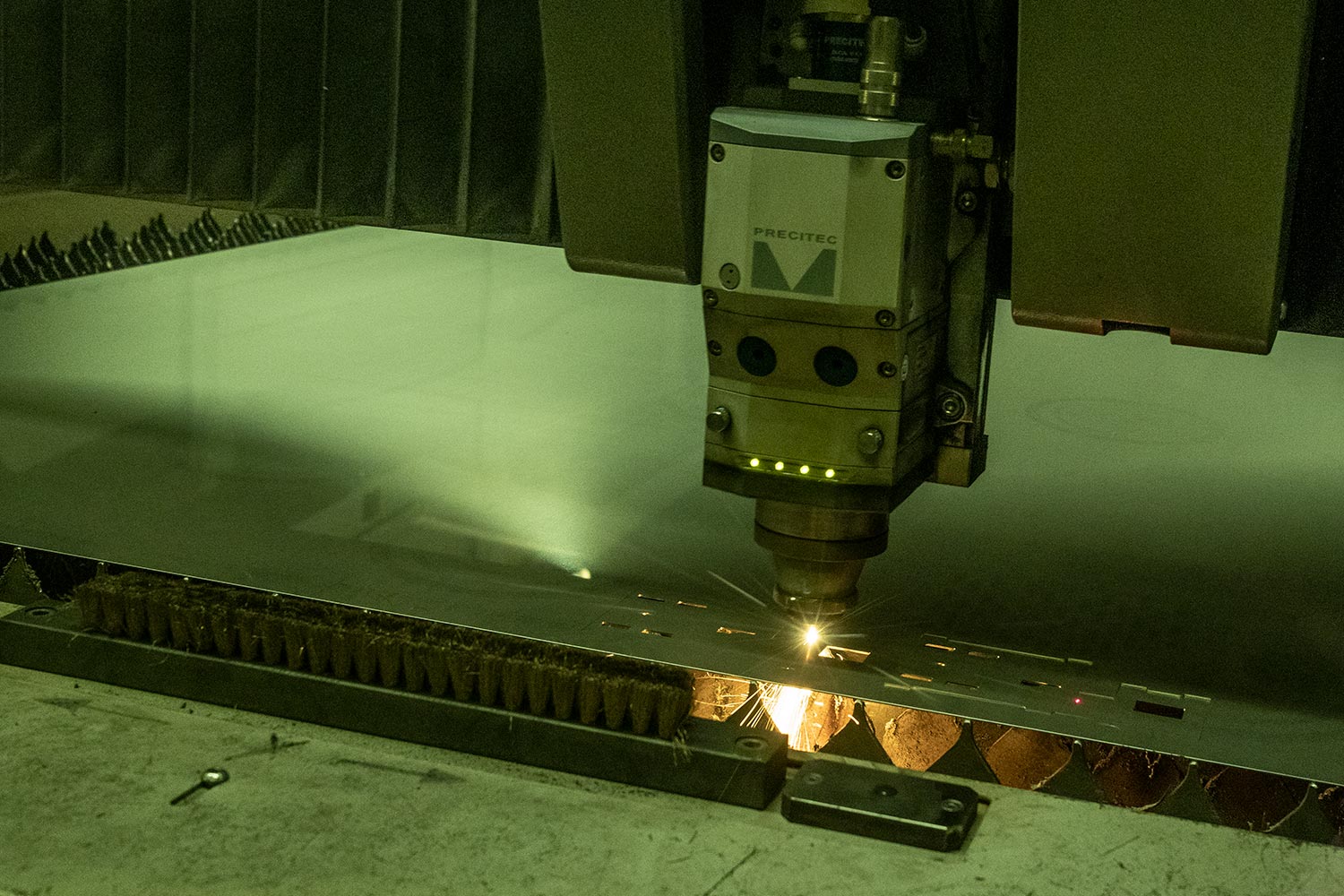

• Taglio Laser

• Piegatura / Saldatura

• Lavorazioni meccaniche

• Parco Macchine

Azienda con sistema di gestione per la qualità certificato secondo la norma UNI EN ISO 9001:2005

Vuoi un supporto tecnico o commerciale? Ricevere informazioni, una consulenza o un preventivo.

© Bomeca S.r.l. unipersonale

REA 301252 – Reg.Imp.VI 97572

P.Iva 03130780244

Strada del Capitello 3/5

36075 Montecchio Maggiore

(Vicenza) – Italy

T. +390444696680

F. +390444490528

PRODOTTI

• Serbatoi

• Attrezzature per l’industria

• Trasportatori sfridi

LAVORAZIONI

• Progettazione

• Taglio Laser

• Piegatura / Saldatura

• Lavorazioni meccaniche

• Parco Macchine

Azienda con sistema di gestione per la qualità certificato secondo la norma UNI EN ISO 9001:2005